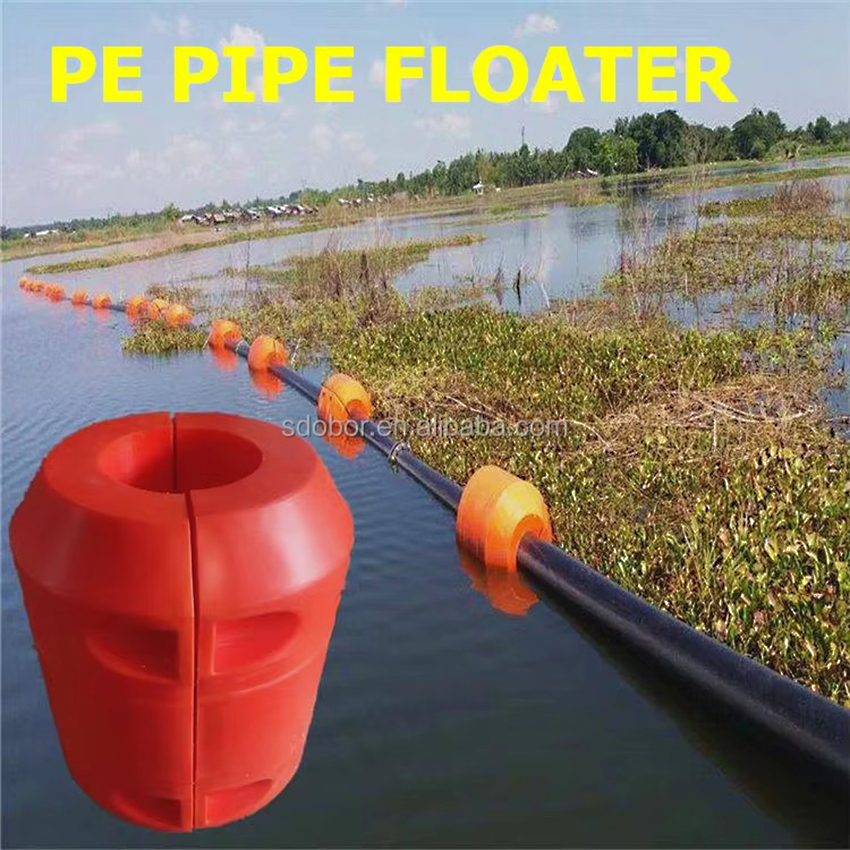

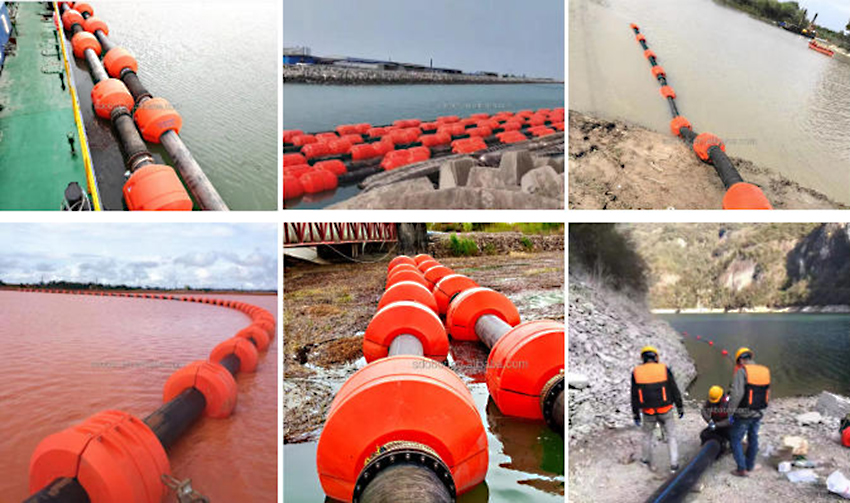

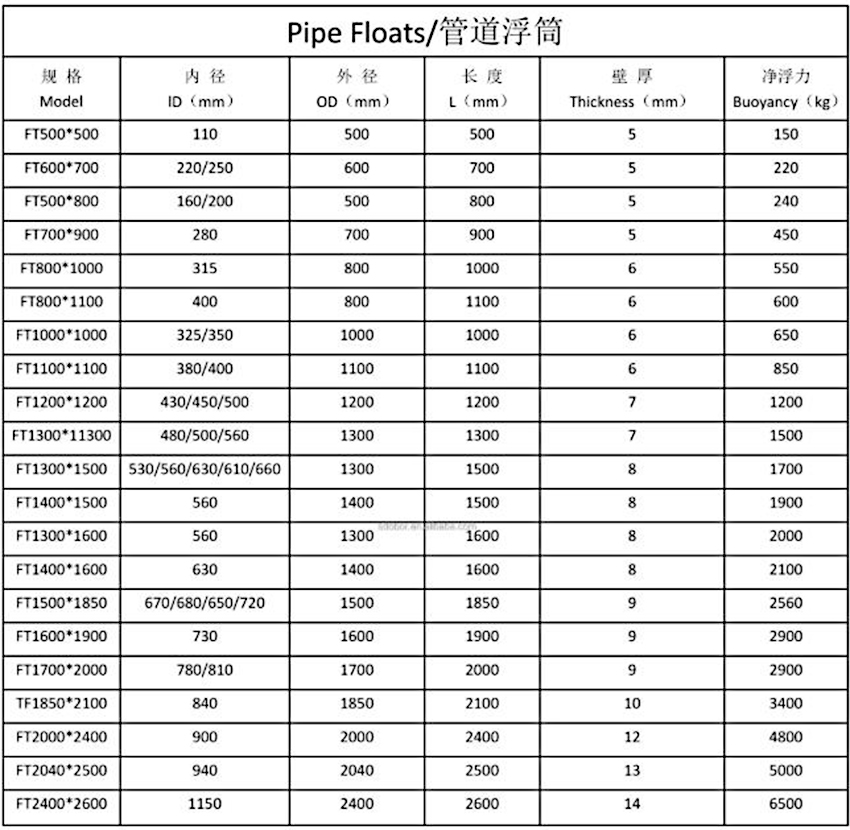

Floater for Dredging Pipeline is one of the important components of dredging pipeline . The key factors for correctly selecting the floater model including the arrangement and layout of the floater, the materials to be transported, the length of the pipeline etc. Finally to calculate the correct floater size, wall thickness, match with the high quality material selection and the filling of the inner EPS foam. All these factors ensure the safe and reliable operation of dredged pipeline.

Characteristic:

1. Low cost of rolling short mold: For products with the same specifications and sizes, the cost of rotoplastic mold is much lower than that of blow molding and injection molding.

2.The edge strength of rotoplastic products is good, and the thickness of the edge of the products is thicker. Solve the problem of thin edges of products in the middle room

3, Rotomolding can be placed in various inlay

4, the shape of rotomolding products can be diversify

5, Rotomolding products can be produced fully closed products, can be filled with foam materials to achieve insulation

7, We can adjust the thickness without modifying the mold

The installation of the pipe float involves preparing the area, placing the float at the designated intervals, and fixing it to the pipe with ropes, chains or straps. Usually, the float is fixed and locked by several bolts assembly. For specific installations, such as the float valve on the drill pipe, before insertion, check the valve hole, the slide valve, and ensure the correct direction.

Name: Sophy

Mobile:+86-13205383163

Tel:+86-538-8997789

Email:obor@sdobor.com

Add:Economic Development Zone, Taian City, Shandong Province, China